Solutions we offered:

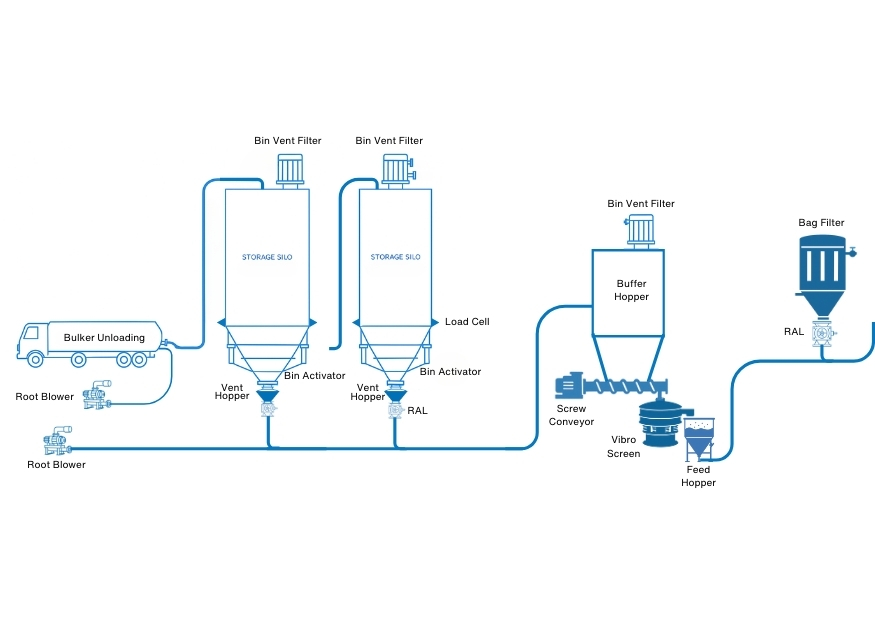

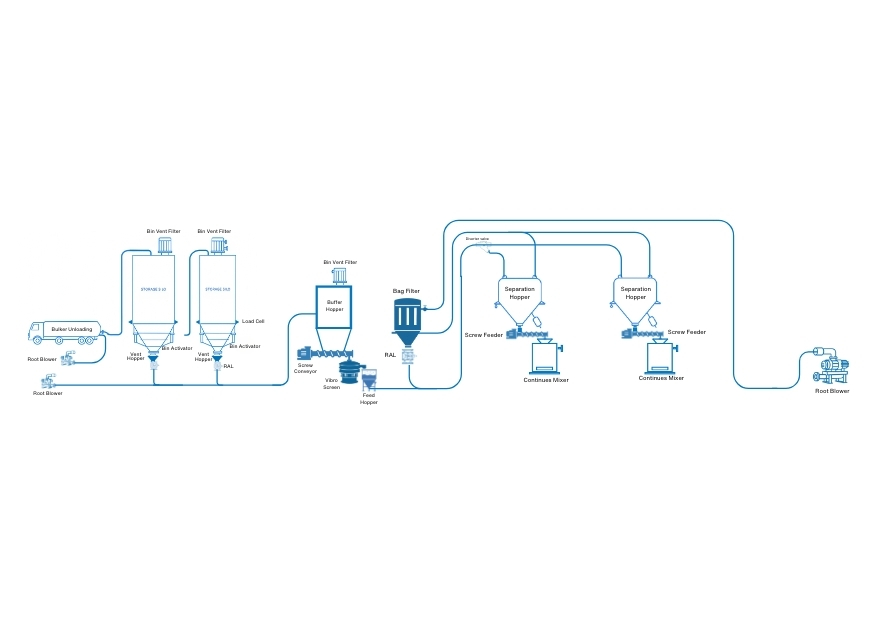

- Dilute phase pressure type pneumatic conveying system for Silo Loading - Capacity: 12 TPH

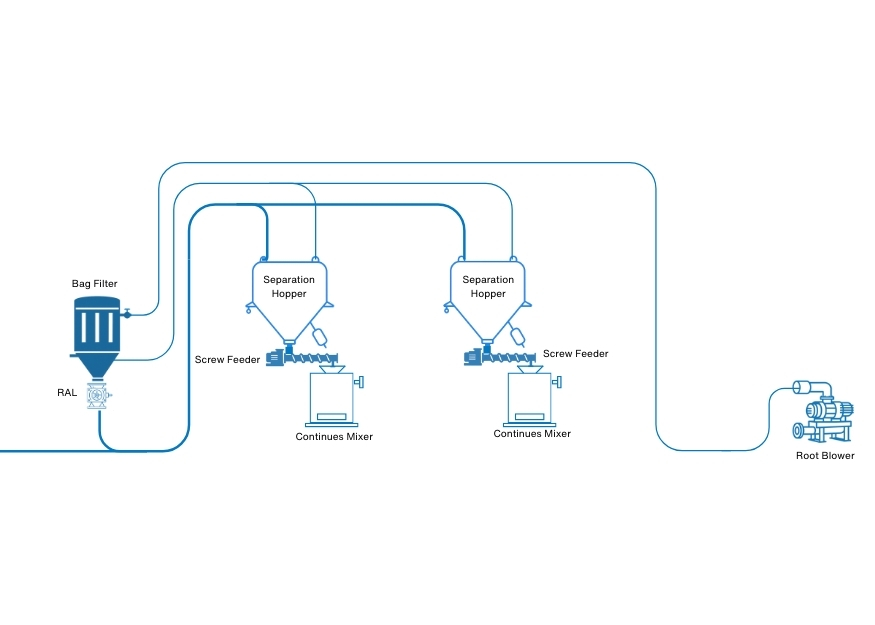

- Dilute phase pressure type pneumatic conveying system for Silo Unloading - Capacity: 6 TPH

- Bulker Unloading System with unloading capacity 12 TPH

- 160 m3 storage silos with accessories including bin activator, circular aeration pads, and bin vent filters

- Buffer hopper equipped with screw feeder and vibro screen, integrated with a dedusting system for hygienic operation

- Rotary airlock valves for controlled, airtight discharge and smooth material flow into pneumatic pipelines

- Automated diverter valve system for distributing material to multiple separation hoppers feeding continuous mixers

- Separation hoppers (1 m³) with level monitoring and butterfly valves for precise batch control

- Bag filters and venting units across the system to ensure dust-free operation and food safety compliance

- Blower system with desiccant dehumidifier and acoustic enclosure for clean, dry conveying air supply

- Centralized PLC-based control system for automated operation, real-time monitoring, and batch traceability

Process Flow Diagrams

Experience the Indpro advantage!

Indpro’s bulk material handling systems are engineered to deliver reliable, efficient, and hygienic solutions for the food processing industry. Designed to meet the unique challenges of handling materials like wheat flour and other food-grade ingredients, these systems ensure safe, contamination-free conveying throughout the production process. From managing raw materials such as flour, starches, and additives to conveying finished products, Indpro’s solutions enhance operational efficiency, product quality, and food safety compliance—making them ideal for diverse applications in the food sector.

It will be our pleasure to help you.

Tell us more about your application needs.